Product Spotlight

Fleet Management Comes to HME

All sorts of industries have tools to help them manage their equipment 'fleets.' Quality Biomedical aims to bring that to its customers with Q-Connect.

- By David Kopf

- Oct 01, 2019

Q-Connect lets

Quality Biomedical

clients see all of

their assets in the

field, and then drill

down on each one

to get the specific

maintenance,

location and other

relevant details on

that unit.

HME providers manage a lot of equipment, and keeping

track of it can be a herculean task. However, to ignore that task is to risk a

considerable amount of inventory investment. Fortunately, there are solutions.

Keeping track of inventory field can be tough, and the problem just gets bigger

as a provider grows. Some larger providers have thousands of assets in the field

with patients. And many of them are very important and life-sustaining assets

such as concentrators, or oxygen concentrators, and ventilators, says Jim Worrell,

Chief Commercial Officer for Quality Biomedical, a company that is well known for

servicing items such as respiratory equipment for HME providers, and that is now

trying to help its customers better manage their HME “fleets.”

“A lot of our customers, when we first engage with them, they really don’t have a

good handle on their equipment service,” he says. “It’s been one of those areas that

been overlooked for a long time. As far as business improvement is concerned, you

look at sales and marketing, you look at facilities, you look at administration, and

regulatory and so forth, but equipment service was just one of those areas that just

always got overlooked.

“Providers really didn’t know what do I have, where is it, when was it last

serviced, how much they have spent on that particular asset, what parts were

replaced, when is the preventative maintenance schedule due, and so forth,” he

continues. “So again, it’s just been one of those areas that really was overlooked

and underserved up until kind of we came into the game.”

And there are multiple costs associated with tracking down equipment that is in

the field, as well, whether it’s for preventative maintenance, repairs, or to reclaim

HME items when patients are done with them. The expenses start compounding

quickly.

“A big part of that expense is not only the expense of the asset itself, but it’s the

expense of sending a truck out to service that asset or retrieve the asset or swap it

out when it goes down or simply when it needs service,” Worrell notes. “Every time

a truck goes out, the number I hear is $75 to $100 just to retrieve an asset. So, yeah,

even smaller providers that have a couple hundred assets, it can be very expensive.”

Finding a Solution

So, in its position as a company that is regularly helping providers handle their

equipment maintenance, Quality Biomedical is very familiar with the equipment-management

challenges providers face. And given that the company is filled with

“ex-IT” guys who have a great deal of familiarity with managing equipment assets

and service, Quality Biomedical started working on a solution, Worrell says.

“We immediately formed a small committee of HME providers and dug into

the process of how equipment service is managed from not only service records

on when was that asset last serviced, but the entire continuum of service management,”

he explains.

The solution they developed from those conversations is Q-Connect, which

stands for Quality Connect. Essentially Q-Connect takes all of a provider’s assets

and puts them into a cloud-based application. The equipment is listed by make,

model, and serial number. Then when a provider that needs to recall a piece of

equipment because, for instance, it has gotten an RMA from the OEM for that item,

the provider can enter a logistics panel and call that item in from the field.

“We have one gentleman who does nothing but organizes trucks to go pick an

asset up wherever it may be,” Worrell explains. “And when the asset is picked up,

and it’s scanned into our facility, the system sends an email automatically that the

asset has been received. And then, the provider can track it all the way through the

service process.

“They can actually watch the asset go through triage, or go to be assigned to

the technician and go to quality control, and then to shipping and so forth,” he

continues. “So there’s no more calling and saying, ‘Where’s my asset? When’s it

going to be delivered?’

Q-Connect also updates and tracks all of the service records for as long as

Quality Biomedical services an asset, which could mean that data lasts for years

and is on-demand to providers whenever they like.

“You just simply click on a serial number and you can see what was done to that

asset, what parts were used, how much money you’ve spent on it, when was it last

maintained, and so forth,” Worrell says. “And then finally, when we ship a product,

the system automatically sends the tracking number. Everything is done by email

and is online.”

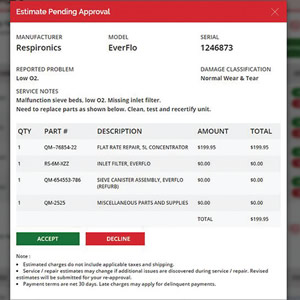

Additionally, providers can go into Q-Connect and review repair estimates and

determine which ones it wants to approve.

“All of the estimates are online,” Worrell says. “You can see exactly what is

quoted, what parts are being used, what we suggest is done with that asset, and

approve the asset or decline the asset. Everything is done electronically. It’s all in

the cloud for easy, self-service.”

And ultimately, that’s what everyone wants these days: self-service tools that put

HME business owners and management back in control, without having to wait for

somebody to call them back.

Q-Connect

Quality Biomedical

(727) 547-6000

qualitybiomedical.com

This article originally appeared in the October 2019 issue of HME Business.

About the Author

David Kopf is the Publisher HME Business, DME Pharmacy and Mobility Management magazines. He was Executive Editor of HME Business and DME Pharmacy from 2008 to 2023. Follow him on LinkedIn at linkedin.com/in/dkopf/ and on Twitter at @postacutenews.